🕒 Last updated on September 2, 2025

A tank built as an engineering marvel turns into a problem

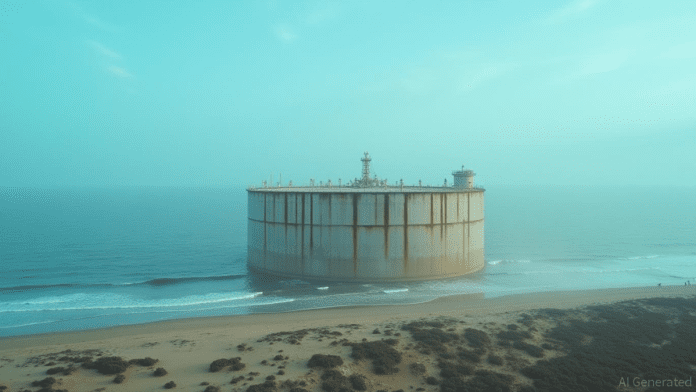

Darwin, the first significant liquefied natural gas (LNG) plant in northern Australia, was established in the early 2000s. At the center of the facility stood a huge storage tank, often compared to a “giant esky,” which towered 48 meters high and stretched 92 meters across. It was heralded as the world’s largest above-ground LNG tank when it went online in 2006.

But soon after the plant started operations, small gas bubbles began rising through the mud near the tank. The operator at the time said the leaks were tiny and posed no real concern. For the next 18 years, the tank stored super-cooled fuel for export to Asia. However, the supply from its Timor Sea source eventually ran out, leaving the tank empty.

Confidential documents now show that the problem was never small. For years, methane, a potent greenhouse gas, had been leaking out of the tank. Experts say the amount could equal the pollution caused by more than 8,000 new cars on the road every single year the tank was in use.

Despite this, the facility is preparing to restart operations. A new project worth more than $5 billion is set to fill the tank again with gas from another Timor Sea field.

A design fault that created a hidden methane leak

The methane problem can be traced back to a fault in the tank’s design. When the first batch of liquefied gas was pumped into it in 2006, the super-cold liquid splashed back against the roof instead of flowing properly inside. The liquid seeped into the space between the tank’s two walls, soaking the insulation and running down into the bottom cavity.

The tank’s outer vapor barrier, made from carbon steel, was not built to withstand such extreme cold. Cracks formed in its weld seams, breaking the seal that was meant to keep gas contained. From that moment, methane began to leak both upwards and downwards—into the air and into the surrounding ground.

Social Security whistleblower Charles Borges resigns after warning of data security risks

Evidence shows that insulating material, which was supposed to stay between the tank’s walls, was even ending up in LNG shipments sent overseas. The tank was permanently damaged, even though the defective equipment was eventually replaced.

For years, handheld gas detectors used at the site picked up nothing unusual. To assess emissions, however, new drone technology was introduced in 2019. The findings were concerning. The tank was emitting up to 184 kg of methane per hour instead of minor leaks. That level was far beyond what the company had been reporting.

The timing was also sensitive. The original operator was in the middle of selling the plant to another gas giant. Internal concerns were raised that the discovery of the leak could affect the sale. In the end, the problem was not disclosed for months. The information only reached the environmental regulator just hours after the facility’s license was extended until 2050.

Public safety fears and official inaction

The leak raised serious concerns about both safety and climate impacts. Methane is dozens of times more destructive than carbon dioxide over short periods of time and contributes to about 25% of global warming. Some officials even questioned whether the leak could increase the risk of explosions that might affect nearby Darwin and Palmerston, only a few kilometers away.

Internal documents show that regulators initially pushed for details about how the company would keep both workers and the public safe. They also suggested that residents near the facility should be informed. However, the operator maintained that there was no impact on anyone outside the plant.

Reports estimated that the tank had been leaking methane at an average rate of 95 kilograms per hour for more than a decade. This amounted to hundreds of thousands of tons of greenhouse gases, much higher than standard industry levels. Yet despite the scale, neither federal nor territory regulators forced the operator to repair the tank or even install accurate equipment to measure the leak.

Later surveys carried out after the plant was sold suggested smaller figures, but campaigners argue the data has been inconsistent. Some estimates suggest the leak could have increased the plant’s overall emissions by up to 25 percent.

Authorities have admitted that fixing the tank would be costly, but instead of requiring repairs, they left the decision to the new operator. Regulators have described the leak as a “concern” but not an immediate risk to human health or the surrounding environment.

The tank has now been empty for several years, but with the new Barossa project set to restart operations, it is expected to be filled once again. Despite calls for urgent repairs, the company has stated the tank is still fit for use and is covered by the required approvals and safety cases.